What It Takes To “Play Ball!” ~ The History of Ordinary Things

Hillerich & Bradsby, Co. and Adirondack, Inc. dominated bat manufacturing during the early days of American baseball history. Following is an abbreviated timeline of the history and the specifications of the Bat and Baseball. You can be an educated fan!

Hillerich & Bradsby, Co.

1884 – Andrew “Bud” Hillerich, a 17-year-old woodworking apprentice, made his 1st professional bat for Pete Browning, a megastar for the Louisville Eclipse, whose nickname was “The Louisville Slugger”.

1894 – “Louisville Slugger” became the registered trademark for Hillerich bats.

1905 – “The Flying Dutchman”, Honus Wagner, a shortstop for the Pittsburgh Pirates, signed a contract with Hillerich. He was the 1st player to endorse a bat.

1911 – Frank Bradsby joined the business to provide marketing expertise.

1916 – The company was renamed Hillerich & Bradsby, Co. (H&B)

WWI & WWII – H&B made equipment for the armed services, producing M-1 carbine gunstocks, track pins for tanks and Billy clubs as well as baseball and softball bats.

Post-War – “Louisville Slugger” dominated baseball as the stick of choice.

1970s – H&B branched into aluminum bats.

2015 – Wilson Sporting Goods bought the brand and continues to produce “Louisville Slugger” bats in Louisville.

Adirondack Bats, Inc.

1945 – Edwin McLaughin and George Millard began making quality white ash wooden bats in upper New York state.

1958 – Adirondack Bats, Inc. logo was developed and added.

1969 – Adirondack introduced the bat-mobile, an Airstream trailer equipped to hand turn bats at Major League spring camps. This easy access strategy converted many big leaguers to the Adirondack “Big Stick”.

1971 – Rawlings acquired Adirondack Industries.

1983 – The logo was changed to “Rawlings”.

Current professional bat specifications: a bat shall be not more than 2 3/4 inches in diameter at the thickest part and not more than 42 inches in length, may be covered or treated with any material or substance to improve the grip.

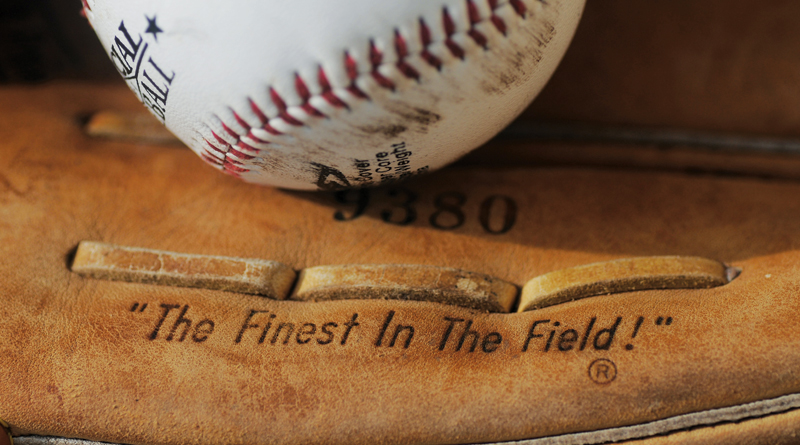

The Baseball

1876 – The National League (NL) was created and set standard rules and regulations for baseballs. A.G. Spalding, a well-known baseball pitcher who made his own balls, convinced the NL to adopt his ball as the official NL baseball.

1934 – The National League and the American League agreed on a standardized baseball with a cushion cork center, two wrappings of yarn, a special rubber cement coating, two more wrappings of yarn, and finally, a horsehide cover.

1974 – Baseball covers were switched from horsehide to cowhide.

1976 – MLB changed from Spalding to Rawlings to produce their baseballs. The stitched balls are hand made in Costa Rica.

Baseball Specifications: a baseball has a rubber or cork center, wrapped in yarn, and covered with two strips of white horsehide or cowhide, tightly stitched together. A major league baseball weighs between 5 to 5 1⁄4 ounces, is 9 to 91⁄4 inches in circumference and is 2 7⁄8 – 3 inches in diameter.

The MLB baseball is hand sewn into 108 double stitches using 88 inches of waxed red string. They are uniquely made for different levels of baseball play determined by the height of the thread seams. Low seams, required by MLB, allow the ball to fly straighter and respond best to the pitcher’s spin. In Little League to college leagues, the seams are markedly higher and easier to grip.

Now, Let’s Play Ball.

- Rain & Shine, A Millennia Of Innovation: The History of Ordinary Things - July 19, 2024

- Crayons Through The Ages ~ The History of Ordinary Things - June 21, 2024

- The Rocking Chair Revolution ~ The History of Ordinary Things - May 24, 2024